Driven by Ecology, Innovation is at the core of OMNIA IN UNO, using extraordinary sustainable materials, respecting the planet and its inhabitants. Fashion is the second most polluting industry in the world, after the oil industry. What is called ‘fast-fashion’ is an ecological and human disaster. Here are a few of its outstanding facts :

- 10% of the global CO2 emissions are from the fashion industry

- 67% of the textile fibers that are being used nowadays come from the petrochemical industry. 70 million barrels of oil are used each year to produce Polyester

- 85% of the ocean plastic pollution is due to micro-plastic coming from synthetic textiles such as Polyester. It represents 22 million tons.

- Regular cotton is the 3rd world water user. More than 10 000 liters of water are needed to make 1kg of cotton.

- 22 000 people are dying each year due to the pesticides used to grow cotton.

You have probably made the same faces as us when discovering those horrific figures. We’ve asked ourselves how can we get dressed without harming the planet and the workers along the chain. Luckily, there are a few alternatives.

We have decided to only use sustainable biodegradable raw material, sometimes extraordinary ones such as hemp, nettle, algæ, soya protein, ginger, mint leaves … it may sound like the recipe for a tasty sushi plate, but it is a matter of fact some very promising sustainable textile fibers.

Every fiber that we use require very little water for their growth. They also help against global warming by harvesting the CO2 from our atmosphere. Some of them have extraordinary perks such as great strength, astonishing smoothness, and help prevent skin diseases thanks to their breathability and anti-bacterial effect.

TENCEL™ / ORGANIC COTTON

For our first collection, we’ve decided to make clothes out of wood. It is indeed possible to create fibers from trees. This fiber is called TENCEL™ Lyocell. It is manufactured by the Austrian company LENZING, who is using wood from sustainable managed forests, also known as FSC. The transformation is done in a closed looped, requires very little amounts of water, and grants the fiber exceptional perks.

The growth of organic cotton does not require the use of pesticides, and very little amount of water compared to regular cotton. The result of this organic growth is a better quality cotton, and can be easily blended with other sustainable fibers in order to find the perfect balance between softness, flexibility and silky aspect. For our first collection, we’re using 67% of TENCEL™ Lyocell with 33% organic cotton. In the end, our products need 90% less water for their manufacture compared to classic cotton.

The ‘made in Europe’ label is a proof of quality and the respect of the working conditions of every employee along the chain. This is the reason why we manufactured our first collection in Portugal, in a family ran factory located in a small village north of Porto. This area is known worldwide for its extraordinary quality of fabrics and garments.

Many certifications exist to assess the wellbeing of the workers and the respect of the environment. We are very proud to have the prestigious GOTS certification for our organic cotton, and OEKO-TEX Standard 100 certification for the end product.

Step 1 - Harvesting

The raw material is harvested and transported to the factory, where it is cleaned and processed to remove any impurities or defects procured during the initial stages of cultivation.

Step 2 - Processing & brushing

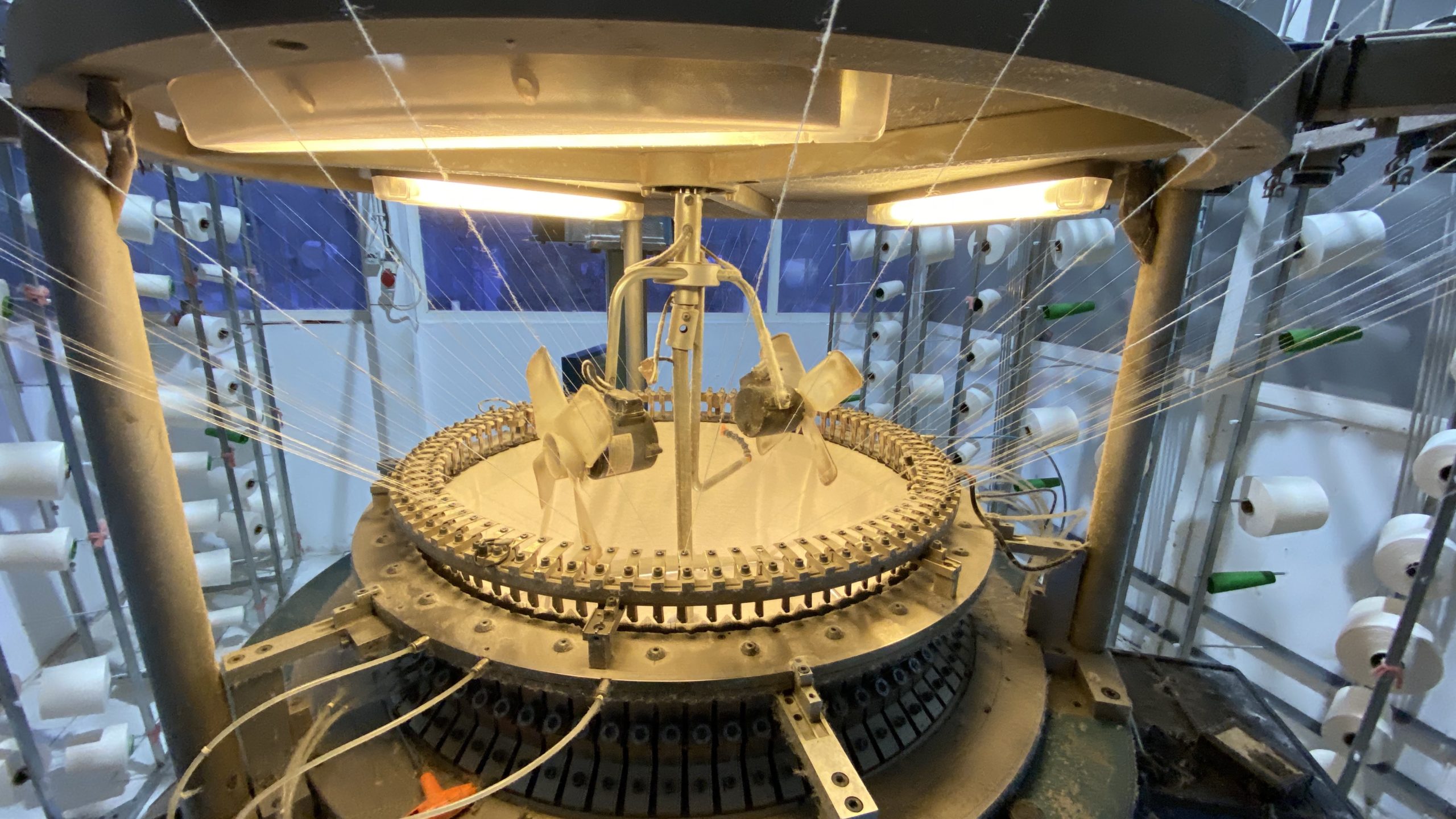

Ring-spun yarn is made by twisting and thinning the cotton strands to make a very fine, strong, soft rope of cotton fibres. The thread is put on a machine that will continue to brush it, to leave only the softest of fibres which will be set onto spool holders.

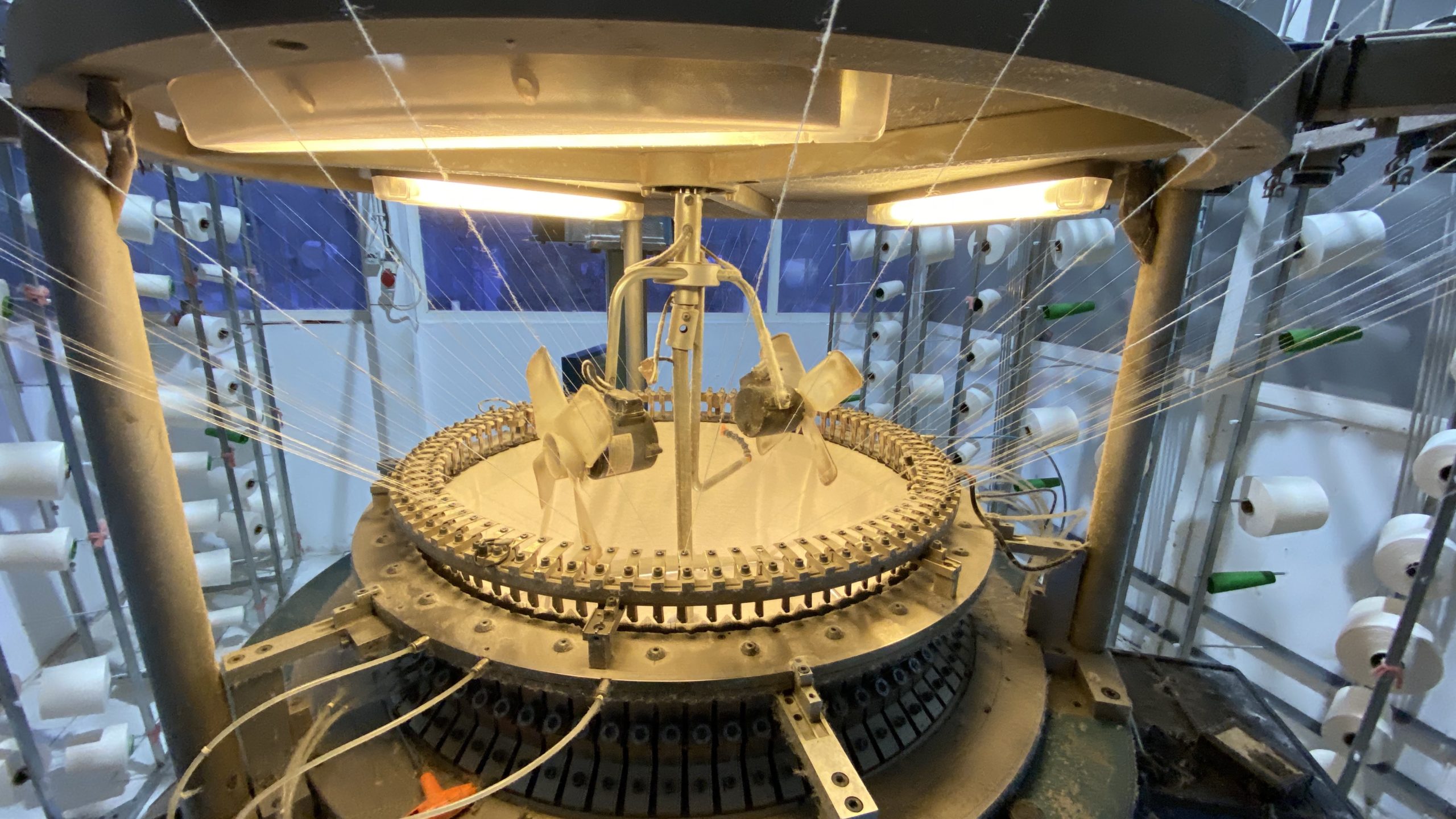

Step 3 - Weaving

The thread is then ready for weaving. This machine weaves the thread finely, creating a piece of fabric.

Step 4 - Dying process & fabric stabilization

Dying process: The roll of fabric will go to the dying machine. Initially, the colour is concentrated in pigmented powder. Once the material is submerged in the water of the machine- a wash takes place at high temperature. The powder and water react together, penetrating the fabric with colour.

Fabric stabilization: The fabric emerges, fully coloured but creased. It needs to be stabilized. It will undergo a series of ironing, steaming, elongating before being put on a roll ready to use for the T-shirt manufacturing.

Step 5 - Cutting & Embroidery

Cutting: The roll will be opened and the cutting process can begin. The different patterns will be used to cut the front of the T-shirt, the back, the sleeves and all the finishing.

Embroidery takes place separately. The front of the T-shirt is sent to the embroidery factory. The patch is then stitched there, and the completed T-shirt front is sent back to the manufacturing company. All the different parts are getting stitched together to make the final product : sleeves, front and back, tags.

The final product undergoes quality control. We remove any stray threads, check for defects and ensure that the product is flawless. After thorough and stringent inspection the t-shirts are ironed and folded ready to expedite.